|

|

|

|

|

|

Home > Product > RF coaxial connectors > SMA

Connectors RF |

|

|

|

|

|

|

SMA Connectors RF (Sub Miniature Version A)

connectors are precision sub Miniature connectors primarily used for higher frequencies with excellent electrical performance from DC through 18 GHz. SMA connectors are primarily used where trends toward higher frequencies, Miniaturization, and SMA connectors are built in accordance with MIL-C-39012 and are available for a variety of flexible and semi-rigid cables. Brass SMA connectors provide a cost effective solution for applications where stainless steel construction is not required.

SMA launchers are the preferred connection element for varied microwave circuits, including hermetically sealed designs. The SMA line covers a huge variety of applications such as Test+Measurement, mobile communications, avionics, etc.

Ref. Product:

RF

Attenuator Fixed

SMA Type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

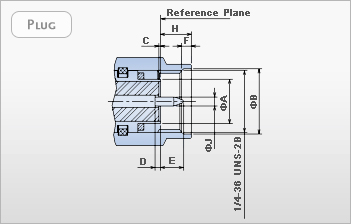

| |

| A |

- |

4.590 |

| B |

6.35 |

- |

| C |

0.00 |

0.25 |

| D |

0.00 |

0.25 |

| E |

- |

2.54 |

| F |

0.38 |

1.14 |

| G |

3.30 |

- |

| H |

- |

3.43 |

| J |

0.90 |

0.94 |

|

|

|

|

|

|

|

|

|

|

| |

| A |

4.59 |

- |

| B |

5.28 |

5.49 |

| C |

0.00 |

0.25 |

| D |

0.00 |

0.25 |

| E |

2.67 |

- |

| F |

0.38 |

1.14 |

| G |

4.32 |

- |

| H |

1.88 |

1.98 |

| J |

5.54 |

- |

| L |

1.24 |

1.29 |

|

|

|

|

|

|

|

|

|

|

|

|

Material Material |

|

Electrical Electrical |

|

| REQUIREMENT |

SPECIFICATION |

|

|

| |

| Body |

Brass or

Stainless Steel

(STS303) |

Au Plated,

Silver Plated,

Nickel Plated |

| Coupling Nut |

Brass or

Stainless Steel

(STS303) |

Au Plated,

Passivate,

Nickel Plated |

| Center Contacts |

Brass or

Beryllium

Copper |

Au Plated,

Silver Plated |

| Insulator |

PTFE Teflon |

| Gasket |

Silicone Rubber |

|

|

|

|

|

|

|

|

| REQUIREMENT |

SPECIFICATION |

|

|

| |

Normal

Impedance |

50§Ù |

| VSWR |

Straight DC~18§× Max. 1.05+0.01×f,

Right Angle DC~6§× Max.1.05+0.03×f,

f: Frequency(§×) |

| Insertion Loss |

0.05× f : Frequency(§×) f : Frequency(§×) |

Insulation

Resistance |

DC 500V 5,000§Û Min. |

Contact

Resistance |

Inner Conductor : 3m§Ù Max.,

Outer Conductor : 2m§Ù Max. |

|

|

|

|

|

|

|

|

|

Mechanical Mechanical |

|

Environmental Environmental |

|

| REQUIREMENT |

SPECIFICATION |

|

|

| |

Coupling Nut

Retention Force |

65Kgf Min.

(Stainless Steel Coupling Nut) |

Coupling Nut

Mating Force |

Proof Torque : 16.5Kgf. Cm,

Recommended Mating Torque :

8~12 Kgf. Cm |

| Center Force |

Engage :1.35Kgf Max.,

Disengage : 0.03Kgf Min. |

Connector

Durability |

500 Cycles MIL-C-39012 |

|

|

|

|

|

|

|

|

| REQUIREMENT |

SPECIFICATION |

|

|

| |

| Vibration |

MIL-STD-202, Method 204 |

| Thermal Shock |

MIL-STD-202, Method 107D,

Test Condition B |

Corrosion

(Salt Spray) |

MIL-STD-202, Method 101D,

Test Condition B |

Humidity

(Steady State) |

MIL-STD-202, Method 103B,

Test Condition B |

|

|

|

|

|

|

|

|

|